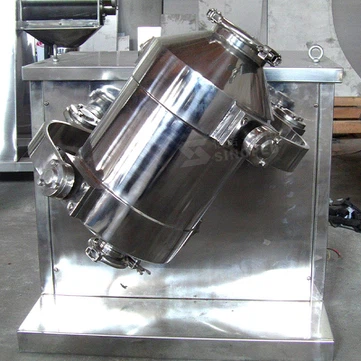

The 3D Movement vertical powder mixer can mix powdery or granular materials with good fluidity and very evenly, so that the mixed materials can reach a mixed state.

The mixing barrel has a multi-directional running action during the operation of the machine, which accelerates the flow and diffusion of various materials in the mixing process. At the same time, it avoids the material gravity segregation and accumulation caused by the centrifugal force of general mixers. There is no dead corner in the mixing, which can effectively ensure the best quality of the mixing.

The working principles

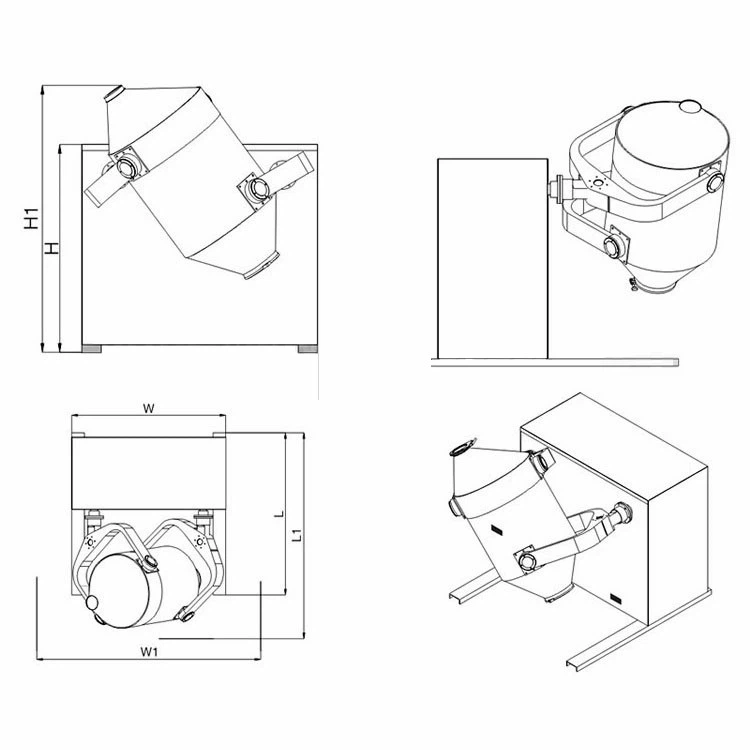

The mixing barrel is suspended at the ends of the driving and driven shafts through two Y-shaped universal joints. The two universal joints are both crossed and perpendicular to each other in space. When the driving shaft is dragged and rotated, the universal joints make the barrel perform compound movements such as translation, rotation and tumbling in space repeatedly. The materials follow the three-dimensional compound movement of axial, radial and circumferential directions in the barrel. The various materials in the barrel flow, diffuse and mix with each other, and finally become uniform.

Structure

The 3D Movement vertical powder mixer consists of the base, driving system, Electric control system, multi-directional, movement mechanism and mixing barrel. The mixing barrel to be in contact with the materials are made of quality stainless steel, with both inside and outside of the barrel mirror polished.

Features

1). This 3D Movement vertical powder mixer is a high-efficiency mixing equipment, which can be used for high-uniform mixing of powdered materials .

2). The components can be evenly mixed under a large weight ratio, and the mixing rate is more than 99.9%.

3). The loading coefficient is high, which can reach 80%and the mixing time is short.

4). The 3D Movement vertical powder mixer has a compact structure, and the motor adopts stepless speed regulation (frequency conversion or electromagnetic), it is very convenient to operate.

5). The mixing barrel is circularly transitioned at all places and has been precisely polished to meet GMP standard.

Technical Parameter Of 3D Movement Vertical Powder Mixer

|

Model |

Barrel volume(L) |

Max. Loading volume(L) |

Max. Loading weight(kg) |

Spindle rotation speed(r/min) |

Motor power(kw) |

Overall size(mm) |

Machine weight(kg) |

|

3DM-10 |

10 |

8 |

5 |

0-15 |

0.55 |

800×1200×1000 |

200 |

|

3DM-50 |

50 |

40 |

25 |

0-15 |

1.1 |

1000×1400×1200 |

300 |

|

3DM-100 |

100 |

80 |

50 |

0-15 |

1.5 |

1200×1700×1500 |

500 |

|

3DM-200 |

200 |

160 |

100 |

0-15 |

2.2 |

1400×1800×1600 |

800 |

|

3DM-300 |

300 |

240 |

150 |

0-15 |

4 |

1800×1950×1800 |

1000 |

|

3DM-400 |

400 |

320 |

200 |

0-15 |

4 |

1800×2100×1950 |

1200 |

|

3DM-500 |

500 |

400 |

250 |

0-15 |

5.5 |

1900×2000×2100 |

1380 |

|

3DM-600 |

600 |

480 |

300 |

0-15 |

5.5 |

1900×2100×2250 |

1500 |

|

3DM-800 |

800 |

640 |

400 |

0-15 |

7.5 |

2200×2600×2600 |

2000 |

|

3DM-1000 |

1000 |

800 |

500 |

0-15 |

7.5 |

2250×2600×2600 |

2500 |

|

3DM-1200 |

1200 |

950 |

600 |

0-15 |

11 |

2400×2800×2800 |

2800 |

|

3DM-1500 |

1500 |

1200 |

750 |

0-15 |

15 |

2500×2950×3000 |

3000 |

Application

The 3D Movement vertical powder mixer is widely used in pharmaceutical, chemical, food, metallurgical, light industry and scientific research units.

Our Equipment packing

Our Company

Our certificates

Our customers' voice

Customer together

Our Exhibition

Hot Tags: three-dimensional movement mixer, China three-dimensional movement mixer manufacturers, suppliers, factory, Freezing Drying Vacuum Dryer, bioreactor, Semi Automatic Capsule Filling Machine, GMP Standard Mixing V Shape Mixer, Plant Tissue Cell Culture Glass Photo Bioreactor, liquid filling machine